Plastic injection insert molding is a plastic injection molding process in which thermoplastic material is molded around an insert piece or pieces placed in the plastic injection molding cavity, resulting in a single strongly bonded, integrated assembly, with the insert or inserts encapsulated by the plastic. Inserts can be metal, another plastic, ceramic or just about any substance that can withstand the plastic injection molding process.

These plastic metal inserted parts can be effectively used in variety of application, we design prototypes, create samples, process mass manufacture of plastic metal inserted parts for various industrial sectors and domestic use.

Our ability:

Our ability:

* Long-term experience for designing and producing for rubber and plastic parts, help the clients to achieve their goal with more cost efficient solution

* Fast and efficient reaction on inquiry * Familiar with various international industry standards

* Skillful techniques on parts structure and dimension confirmation (3D scan, CAD, Pro/E and UG)

* Design rubber formula and mix rubber compound ourselves, choose suitable plastic material from reliable worldwide suppliers

* Sample check by 3D print or one cavity mould

* Mould design and manufacture by ourselves

* Professional on quality control and products inspection

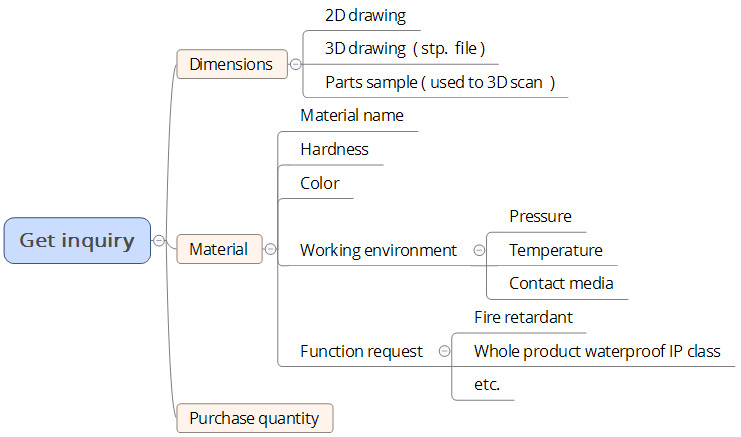

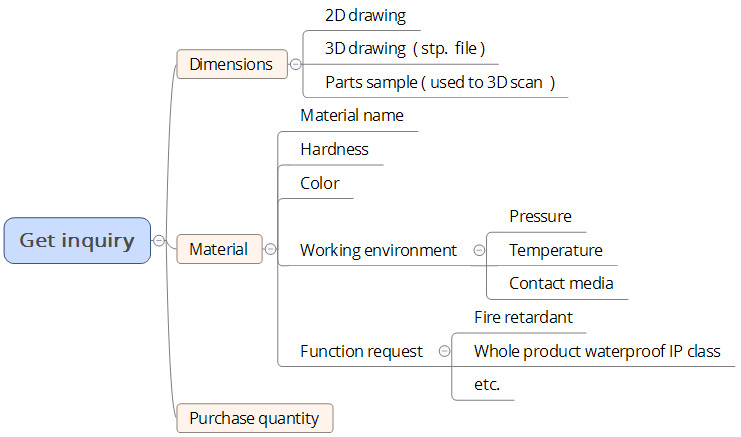

Flow chart for different inquires