Bolted tank stripping gaskets are slit-to-width rolls of rubber with holes punched at precise uniform intervals, perfectly suited to sealing between bolted or riveted panels of medium to large sized tanks, as well as sealing large rectangle flanges with uniform holes. Changzhou Meridian makes these items according to your different sizes or technical specification with any type of rubber by stripping, cutting, drilling and etc. The typical application: Door seals for silos and tank to provide sealing for products such as sugar, flour, oils, chemicals and beverages.

Available Tank Stripping Materials

Popular varieties include Neoprene for general purposes, Nitrile Rubber (Buna-N) for petroleum products.

The superior weather resistance of EPDM also makes it a good economical general purpose tank sealing material.

Silicone/MVQ rubber tank stripping is suitable for both low and high temperature extremes as well as food and medical products.

Fluoroelastomer (Viton / FKM) rubbers are suitable for both high temperatures and chemically volatile environments.

Reinforced Bolted Tank Stripping is cloth inserted rubber tank stripping. Available in numerous insert options, the supporting layer of cloth or nylon inhibits rubber from extruding under pressure without compromising its ability to conform and seal the surfaces.

We can also manufacture punched tank stripping out of sponge rubber, foam, plastic, and various non-rubber gasket sheeting materials. The typical application: Door seals for silos and tank to provide sealing for products such as sugar, flour, oils, chemicals and beverages.

Available Sizes & Thickness

Available Sizes & Thickness

The combination of material thickness and hardness are the primary elements affecting the conformance of a seal to the tank panel surfaces (i.e. a thicker, softer material will be more inclined to seal irregular surfaces with less torque). However, greater thickness is also a detriment for two reasons, cost and weight.

Since these rolls must be carried to often high or otherwise difficult to reach areas, thinner material allows more length of seal to be carried on a roll for less weight during construction of the tank. Longer rolls also yield less downtime for getting new rolls.

Typically, our clients find thicknesses between 1/16″ (1.6mm) and 1/4″ (6.4mm) suitable for most tank sealing applications, with 1/8″(3.2mm) being a popular choice. This, however, is not a limitation.

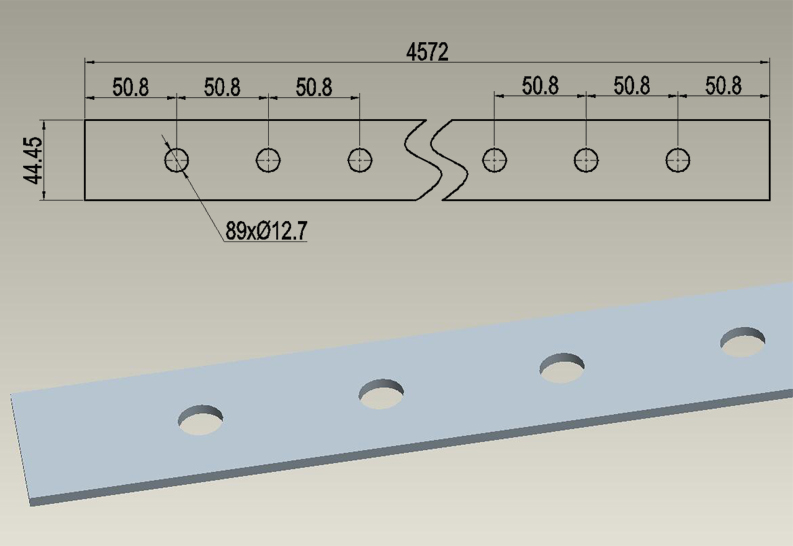

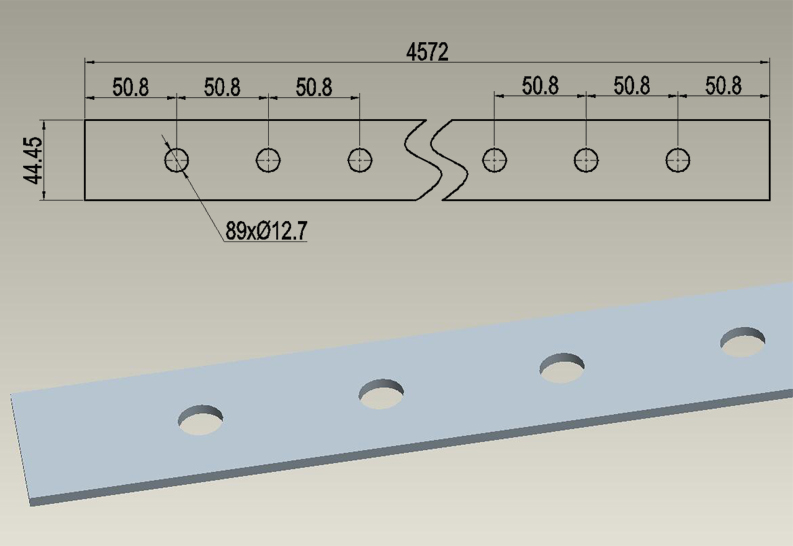

Hole Shapes, Sizes, and Spacing

We can manufacture continuous length punched gasket stripping, plus single and double-punched varieties as standards, but can manufacture virtually any hole pattern, and can even supply oval, square, or alternate shaped holes.

Seal Length & Width

We could conceivably manufacture continuous length tank seals in widths as low as 1/2″(12.7mm) or as wide as 60″(1524mm) of some materials, which means about whatever any one could want. Like material thickness, greater seal width may improve sealing effectiveness, but also increases cost and weight.

Tank stripping is usually sold by the lineal foot, which is generally determined by the uncut roll size, which varies by thickness and variety between 25ft (7.62m) and 100ft (30.48m) lengths. Naturally, we can generally cater to special requirements on roll length.

Packaging

Changzhou Meridian can do customized packaging as per your requirement, include laser inscription and screen printing.